Before you begin trimming your canopy trim the protective film back away from the line. Tape the edges down with clear packing tape, also tape any seams of the protective film. This will prevent acrylic chips and dust from getting under the film. An abrasive wheel powered by a drill, Dremel tool, or a die grinder is recommended. Reciprocating saws like jigsaws or sabre saws are not recommended and will probably break your canopy. A tool that grinds the canopy is best. Mark your canopy with a grease pencil or Sharpie. Allow the canopy to warm to room temperature. Don’t allow the canopy to vibrate or chatter while cutting or it may chip or crack. Support your canopy so it will not twist or spread during trimming. Duct tape is handy to hold things in place. Cut slowly, do not push the cutter. Let the tool do the work. Use eye protection. Acrylic chips can be a problem in your eyes since they are clear and difficult to see. After the canopy is trimmed, use the hand-held belt sander (we prefer the 3”x18” 40-60 grit) to sand down to your line. De-burr the edge with a scraper or sandpaper before trial fitting to keep from breaking the canopy or cutting your fingers. |

Use cleaners specifically for acrylic. A damp cloth or an air blast will clean the dust away. To achieve the best results use fore and aft motion instead of a circular motion. To clean dirty acrylics use plenty of water and non-abrasive soap or detergent. All-cotton flannel can be used for drying. Never use aromatic solvents such as acetone, benzene, carbon tetrachloride, lighter fluid, lacquer thinners, gasoline, window sprays, concentrated alcohol, ketones or scouring compounds. Avoid using cleaners with ammonia, such as 409. Grease, oil or tape residue may be removed with kerosene, white gasoline, naphtha or isopropyl alcohol ( Do no use isopropyl alcohol on extruded acrylic - the Panther canopy is made from Cast Acrylic). Mineral spirits is our favorite. Wash approved solvents off of canopy with Dawn dish washing liquid or equivalent and water followed by a clear water rinse. To prevent water spots, blow dry with compressed air or wipe dry with soft cotton flannel. |

Small scratches can be buffed out with Novus #2 or #3 depending on the severity of the scratch. For deep scratch removal, use Micro Mesh or 3M Window Repair Kits. Avoid removing scratches in critical areas where optics are important. The optics are almost always worse after the repair then the original scratch. |

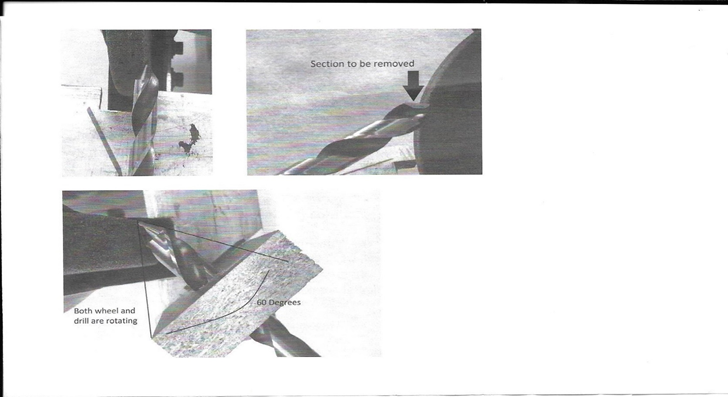

When drilling acrylic, best results will be obtained using commercially available acrylic drill bits ( We recommend the Diamond Dust drill bits available from Craftics). If the desired hole is larger then 3/16”, drill with a Diamond Dust drill bit first and then enlarge with the Unibit #2 (New styles should not be used to drill a 3/16” hole due to the aggressive nature of the SpeedPoint.) For Holes larger then 3/8” different techniques can be used. Hole saws and two-flute Vortex router bits are a few options available. Drill several practice holes in scrap pieces of acrylic to perfect these techniques before drilling your part. Back-up the canopy with a block of wood. Start with a slow speed and light pressure, then increase the speed and pressure. As the drill bit starts to go through the acrylic, reduce the speed and pressure so the drill bit goes through the acrylic slowly. Drill holes oversize to allow for motion caused by thermal expansion and contraction. Lightly de-burr the hole with a countersink we prefer the single flute style. When precision countersinking is desired we recommend using a microstop. DO NOT USE LOC-TITE. It crazes the acrylic. If a commercially available acrylic drill bit is not available then a high speed steel twist drill bit can be modified to work as shown in pictures below. Chuck the bit in an electric drill. Insert the bit though a wood or metal bushing clamped to the support rest of an abrasive wheel. The bushing must be clamped so that an approximate 60 degree total included angle is ground on the bit. With the electric drill operating, insert the bit through the bushing so that it contacts the face of the rotating abrasive wheel, thus grinding a conical point to the bit. Remove the bit from the chuck. Using the side of the rotating abrasive wheel grind a zero rake angle on each of the cutting edges. This provides a scraping, rather then a cutting action. Then use the face of the rotating abrasive wheel to grind a clearance behind each of the cutting edges. Make sure to practice drilling holes with the finished bit in scrap pieces of acrylic.

|