Note – Use caution! It is suggested you use a drill stop through the following procedures as it is easy to damage the opposing skins when drilling on the relatively thin cross sections of the control surfaces.

** NOTE - Regarding rivet options for hinge: The side of the hinge that attaches to the control surface will be a protruding head rivet, EXCEPT for the trim tab (depends if you are using countersunk or protruding head rivets on your skin). The side of the hinge that attaches to the main structure will use the rivet type you are using on the skin, and length according to rivet length guidelines.

**Note - some builders prefer stainless steel rivets on the hinges for the additional shear strength.

1. Prepare all parts according to Parts Preparation

Note - The two outer ribs face inboard (toward the fuselage) and the inner rib (farthest left) faces outboard. See plans for more detail.

2.Starting with center rib – fit the rib to the lower side of the skin, ensuring the rib center line is aligned with the pilot holes and is sitting against both the lower skin and the forward skin. When satisfied with the fit – drill #40 and cleco to the both lower and forward side of the skin.

Tip – It can be difficult to fit the center rib. Another method is to fit the outboard end rib and drill #40, then move the rib to the center and cleco.

3.Repeat with the two inboard ribs.

Note - The inboard rib needs to be slightly trimmed and front flange needs to be bent slightly more for the proper angle. Revision 1.1 and higher kit parts have this custom rib included as part number 1049 with description P-T-HT-E-inner rib-PA.020-R1-q1.

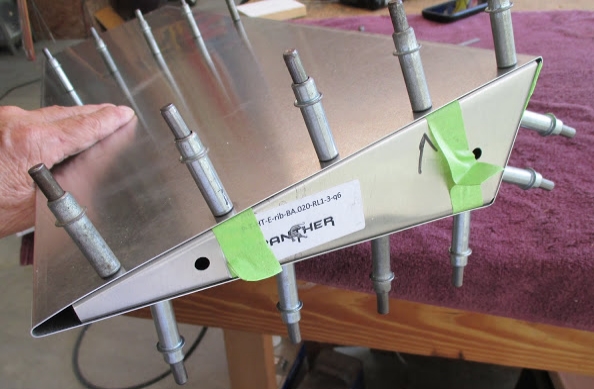

See photo below and plans page P-T-HT-PA, Misc Details for a detailed drawing.

4.Flip the elevator so the top is facing up and place onto 2 leveled 2” x 4” blocks spaced so they clear the clecos in the bottom of the skin.

5.Line up the center lines with the skin pilot holes and ensure the trailing edge profile is correct (ie. - not skewed up or down, but in plane with the ribs)

6.Drill with #40 and cleco the top surface.

7.Uncleco the top skin and tuck the flange from the upper surface of the skin behind the front of the skin and re-cleco the upper surface. This prevents the relatively flexible front skin from bending away from the drill bit when drilling the hinge in the next step.

8.Prepare the P-T-HT-E-elevator hinge per the plan sheet by drilling holes at specified spacing.

9.Ensure the elevator is level on both ends and has no twists or bows.

10.Align and drill #40 and cleco the hinge to the elevator using a drill stop and light pressure to prevent damage to the upper skin.

11.Up drill #30 assembly replacing clecos as you go with the proper size.

12.Disassemble and deburr – dimple skins and ribs if using flush rivets for skins

Note – do not use flush rivets on the hinges

13. DO NOT Rivet the inboard rib to the elevator assembly until the elevator joiner arm (welded assembly) is fitted. Re-assemble remaining parts and rivet using chosen rivets, using caution to ensure the assembly remains twist free.