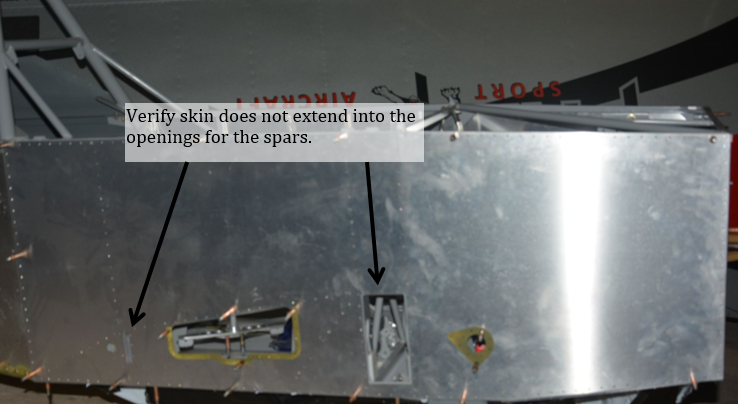

1. Fit fuselage side skins to forward fuselage frame. Skin should be centered vertically approximately or 1/16“(1.6mm) in from top and bottom tube. Skin should be flush to aft edge of the rearmost fuselage tube, and be approximately 1/16” (1.6mm) from forward edge of forward most fuselage tube. Mark skin and fuselage tubes the same as the bottom skin. Remove the skin and check that all rivets are centered on the tubes. Adjust and repeat a necessary for the best fit. Also verify the skin clears the spar “box” area. After aligned, clamp skin and transfer drill all #40 holes from the skin into the fuselage frame. See notes above before drilling. Repeat for the other side skin.

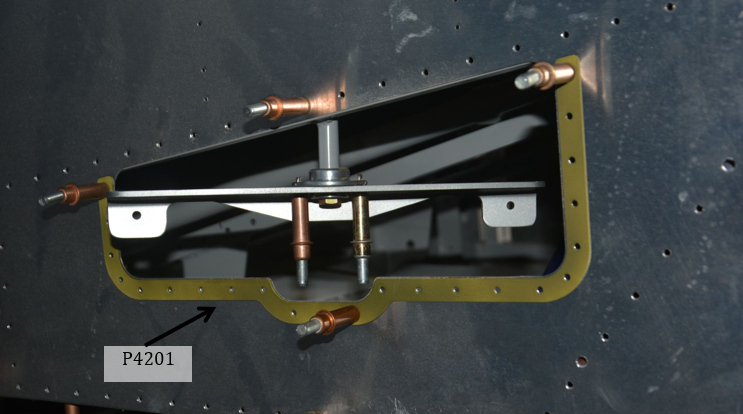

2. Locate stiffener for aileron paddle cutout (P4201). Updrill to #30 deburr and rivet with BSPS-42 rivets, with the rivet head inside the cockpit. These stiffeners will be hidden when the wing is installed, and the rivet head gives a cleaner look inside the cockpit. Repeat for the other side

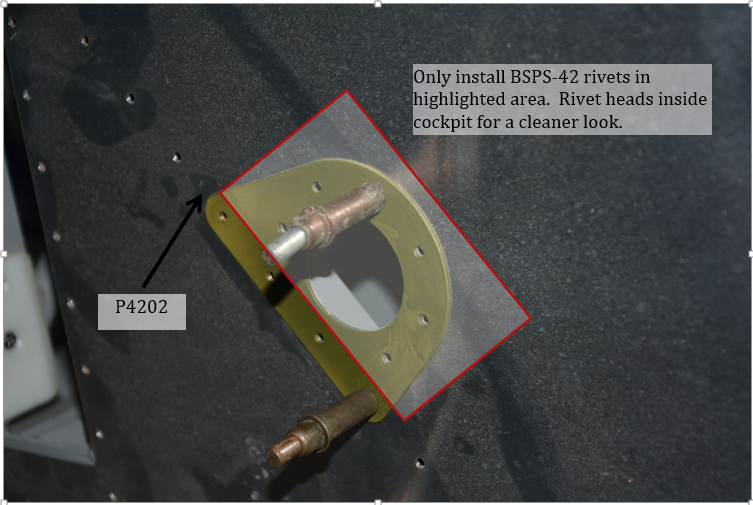

3. Locate stiffener for the fuel line disconnect (P4202), cleco inplace and updrill to #30. Deburr and rivet with BSPS-42, only in holes that DO NOT go through the fuselage tubes. Rivet heads should be inside the cockpit for a cleaner look, again this area is covered by the wing. Repeat for the other side.

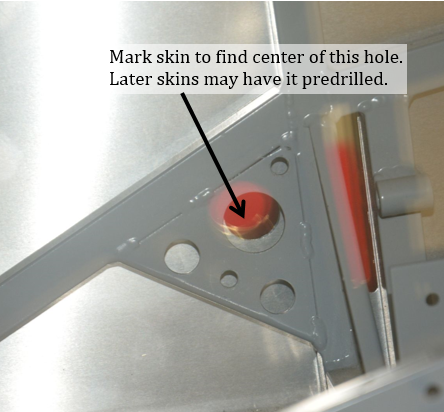

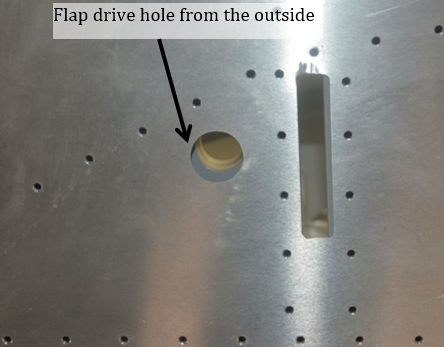

4. Mark hole in side skins for the flap drive tube. The hole in the frame is 1” (25.4mm), the hole you drill in the skin should be ¾” (19mm). Note: These holes may be predrilled. The ¾ (19 mm) should be centered on the 1” (25.4 mm) hole (picture for representation, may show hole off center)