Firewall to Mount Hardware required

Lycoming DynoFocal Mount to Firewall Hardware

oQty 2 - AN6-36A Bolts for the Top

oQty 3 - AN6-34A Bolts for the Bottom

oQty 5 - AN960-616 Washers

oQty 5 - MS21042L6 Nuts

All other engine mounts from SPA to Firewall Hardware

oQty 5 - AN6-36A Bolts for the Top

oQty 5 - AN960-616 Washers

oQty 5 - MS21042L6 Nuts

Engine to Engine Mount Hardware

Lycoming DynoFocal Engine to Engine Mount Hardware

oMount bushings - Aircraft Spruce #08-03500

oBolts - TBD

oWashers - TBD

oNuts - TBD

Corvair Engine to Engine Mount Hardware

oBushings - Energy Suspension PN 9.8105R from Summit Racing

oBolts - Qty 4 AN6-36

oNuts - Qty 4 AN310-6

oWashers - included in bushing set.

oPlastic tubing - goes over the bolt where it passes through the Corvair's Case. See Corvair Conversion Manual for more details. 1/2" long piece of 1/2" O.D. by 3/8" I.D. soft plastic tubing.

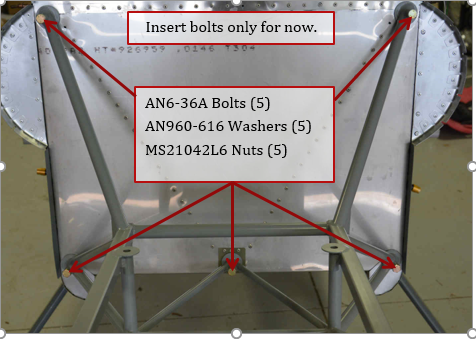

Installation Instructions

1. Corvair engine mount is shown below along with the hardware, but all engine mounts use the same pattern to attach to the fuselage. However, the bolts will be a different lengths and thicknesses depending on the engine mount (see above). Please use this as a guide for your particular engine mount.

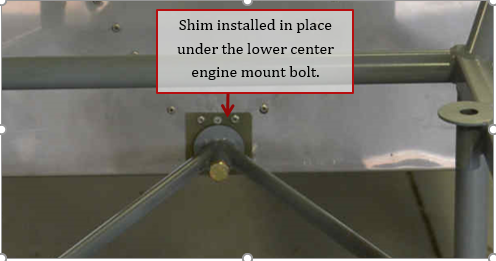

2. The lower center engine mount bolt location is not as rigidly fixed as the other 4. As a result, it can vary slightly more during the welding process. Hold the engine mount tight against the firewall and check what the distance is between the firewall and the engine mount. A 0.032” shim was made in part 1 of this manual, if the gap is more than 0.032” you can shim as required to fill the gap. Once the shims have been determined and in place, attach them to the firewall using appropriate stainless steel rivets. (grip length will be determined by your shims.)

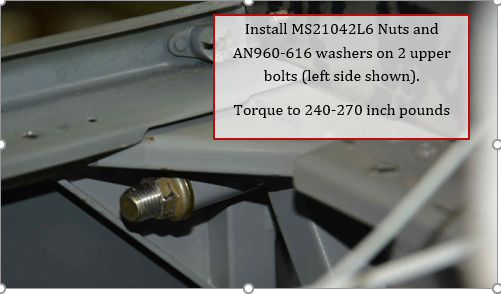

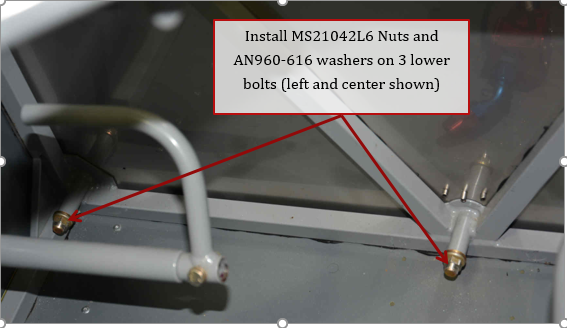

3. Install MS21042L6 Nuts and AN960-616 Washers in 5 places. Torque to 240-270 inch pounds (160-190 inch pounds from AC43.13 manual + 80 inch pounds friction drag torque of self-locking nut)