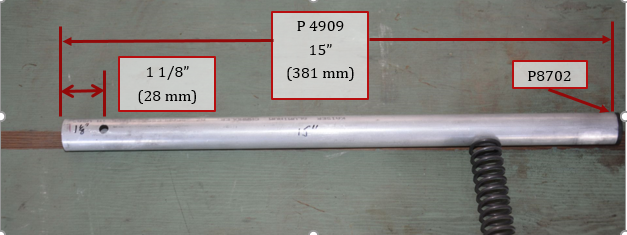

1.P4909 P-F-Inner Flap Handle Tube-AT.875"x.065"x15"-q1, tube is 6061 T6 7/8” (.875”) OD .065 wall. Overall tube length is 15”. Cut tube to length, and mark for a hole 1 1/8” up from end.

2.P8701 Spring shown above is provided in the finishing hardware kit offered by SPA – P8700. Spring is OD .875 and 3” long. McMaster Carr Part number 9657K18.

3.Cap (button) for tube is also in hardware kit P8700. Mc Master Carr Part number 9283K13.

Using a drill press and V-Block drill a ¼” hole in spot marked in previous step. Hole should be as close to the center of the tube as you can get. Drill the hole in steps starting with a #40 drill bit. If the hole is off center, the bolt will not fit through the slot in the control handle.

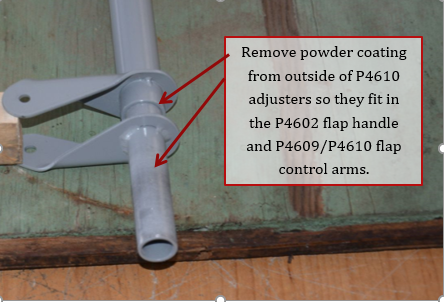

3. The P4610 adjusters may have to have some of the powder coating removed in order for them to fit in the P4602 flap handle and P4608/P4609 Flap control arms. They can be touched up with paint and assembled with anti-seize compound for assembly.

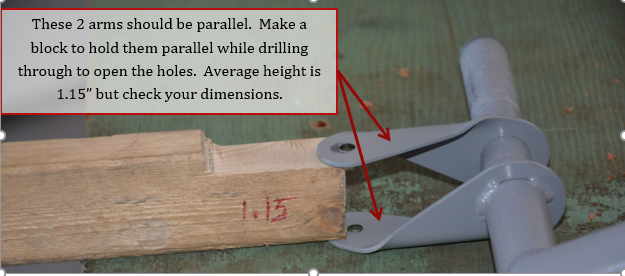

4. Make a shim that is the correct thickness in order to make the 2 halves of the adjuster arms parallel with each other. It should be around 1.15” thick, yours might be slightly different.

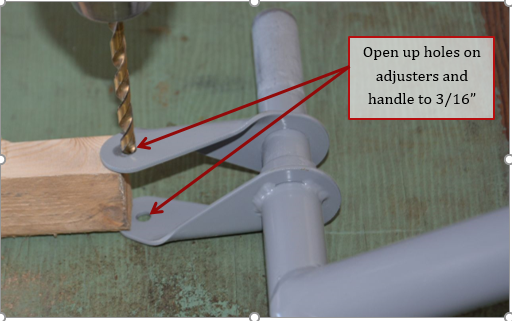

5. Open up the holes to #11 0.191”. Do this for the other adjuster also. Save the shim, because it will come in handy later on.

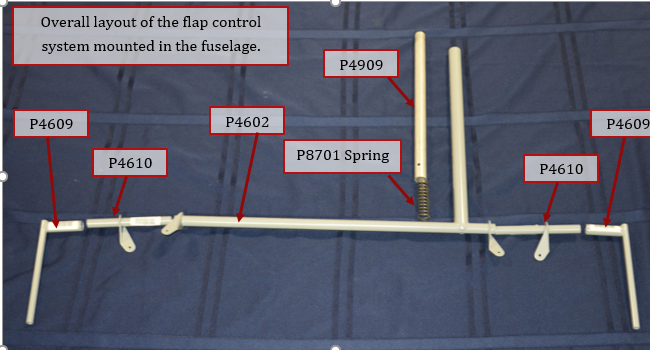

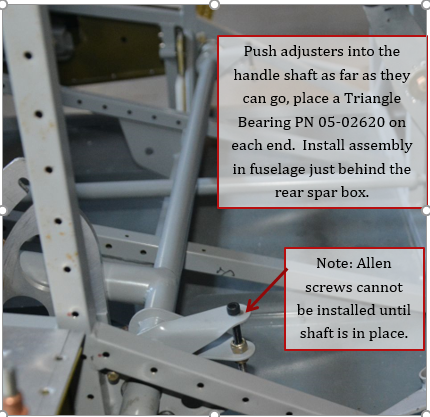

6. Push adjusters in as far as you can into the handle, place 2 triangle bearings 05-02620 onto adjusters. Slide entire assembly into holes on fuselage just behind the rear spars

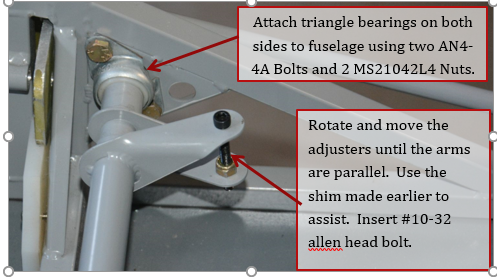

7. Bolt the 2 bearings in place using AN4-4A bolts and MS21042L4 nuts (2). Align joiners to allow #10-32 1 ¾” allen head bolt through the holes in adjusters and handle. Use the shim made previously to make the arms on the adjuster and handle parallel.

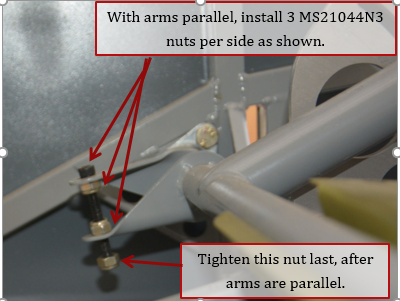

8. Install 3 MS21044N3 nuts on allen head bolt as shown. Make sure arms are still parallel. Repeat for other side.

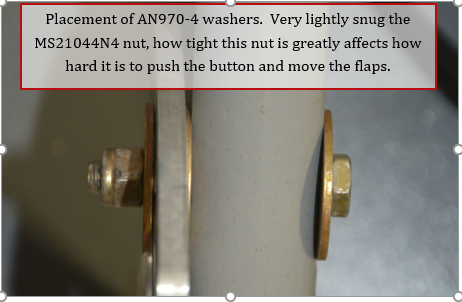

9. Insert spring (P8701) into the flap handle. Apply a light coating of an anti-seize compound on the inner tube, keep the upper 1” to 1 1/2” free of compound. Insert tube (P4909) into flap handle and install cap (P8702) in end of tube. Push AN4-16A bolt with 3 AN970-4 washers as shown through slot in the handle and the hole drilled in the inner tube. You only want to tighten the MS21044N4 nut enough to keep washers from moving. How tight you make this bolt directly affects how hard it is to push the button.