The Lower tail cone is assembled upside down on a flat surface. This can be a table, or two saw horses with the top surfaces in the same plane.

Note: The surface tops MUST be in the same plane to help avoid building twist into tail cone

The lower tail cone skins and bulkheads are matched drilled so it will cleco together quickly with little room for error

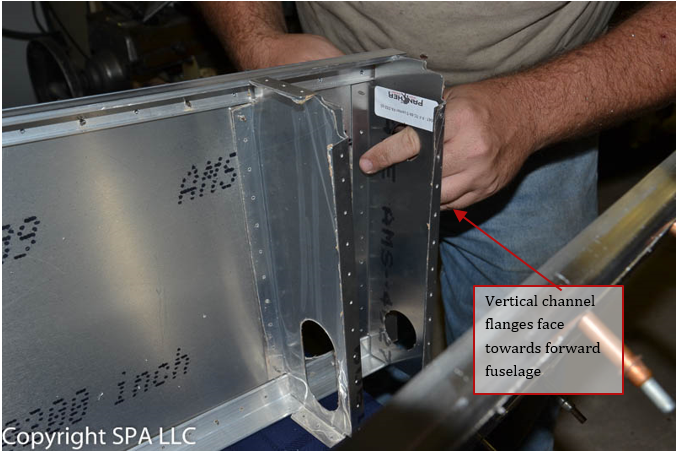

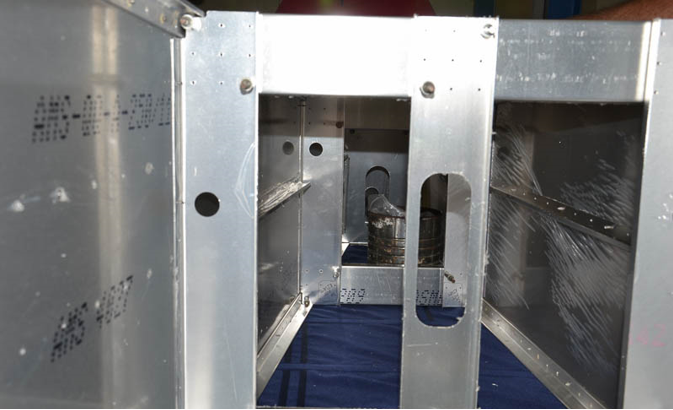

1.Using plans sheet P-F-TC-lower TC as a guide, cleco the sides and bulkheads together

2.Lay P-F-TC –bottom skin (p6406) into the “step” in lower longeron and cleco at each bulkhead

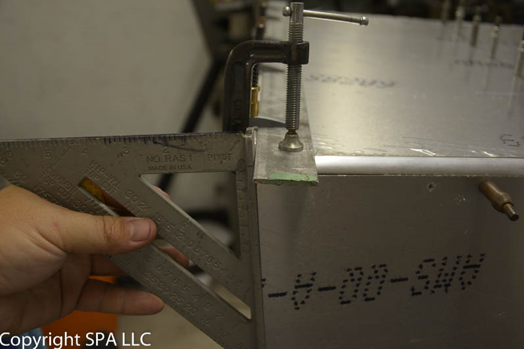

3.Measure from front edge of bottom skin to front edge of side skin and verify that the dimension is the same on both sides. Adjust if needed and use a small clamp to “lock” in any adjustment. This will ensure the TC bulkheads a perpendicular to the Center line.

4. We clamp a straight edge aligned with the side skin as shown below

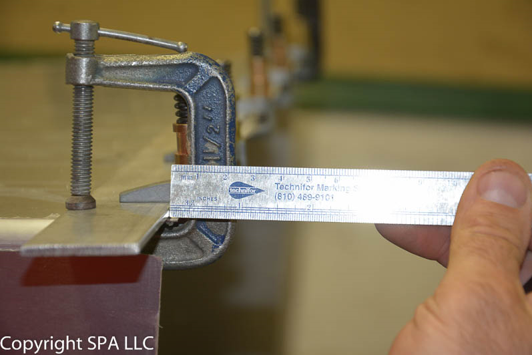

5.Then measure from edge of bottom skin to straight edge. If not the same verify the table top or saw horses are in same plane so the tail cone is not twisted. If needed adjust the TC sides front or aft to make this measurements the same and clamp in place.

6.Work from aft to front drill #30 and cleco the bottom skin to the longerons, verifying a good fit into the “step” in lower longeron.

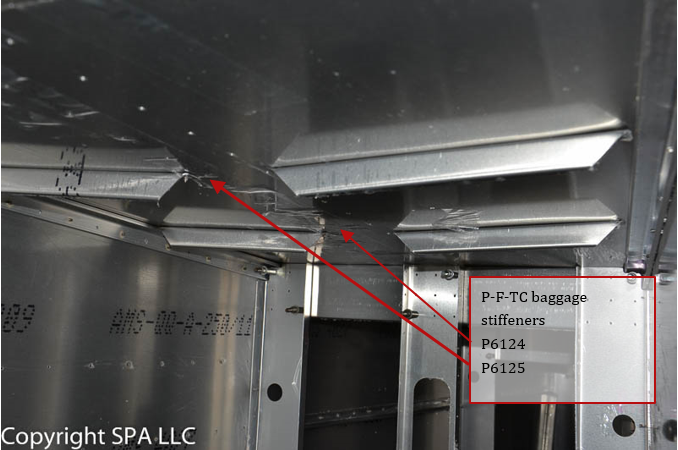

7.Cleco the P-F-TC-baggage stiffeners 1 and 2 (P6124 qty 2, P6125 qty 2) onto the bottom skin

8. Up drill and cleco the bottom skin, longerons, bulkheads, and stiffeners to #30. DO NOT Rivet at this time.