Note : The engine mount must be permanently installed to install the Nose Gear Leg and shock absorber. You may wish to temporarily install the engine mount and Nose Gear system before final installation see here for Engine Mount installation information

Note: DO NOT SIT IN FUSELAGE OR INSTALL THE ENGINE WITHOUT THE FORWARD SIDE SKINS RIVETED IN PLACE . The forward fuselage is a "stressed skin" design and damage WILL occur to the steel frame with out the skins attached.

Note: The P8614 nose gear strut is heat treated . DO NOT drill, (except for Fork Nut Cotter Pin)or welded (repairs etc) on the strut .

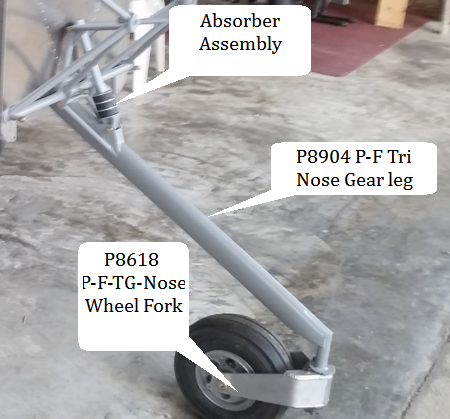

The Panther tri gear utilizes a "rigid" (not flexible) streamlined 4130 Leg with a pivot at the firewall and a "absorber" to dampened movement and absorb shock. The nose wheel is castering with stops to prevent the assembly for rotating "backward" and possibly getting in the propeller arc. Steering on ground at very low speeds is with differential breaking, and at fast taxi speeds and higher is through rudder (aerodynamic). The nose gear system attaches only to the engine mount

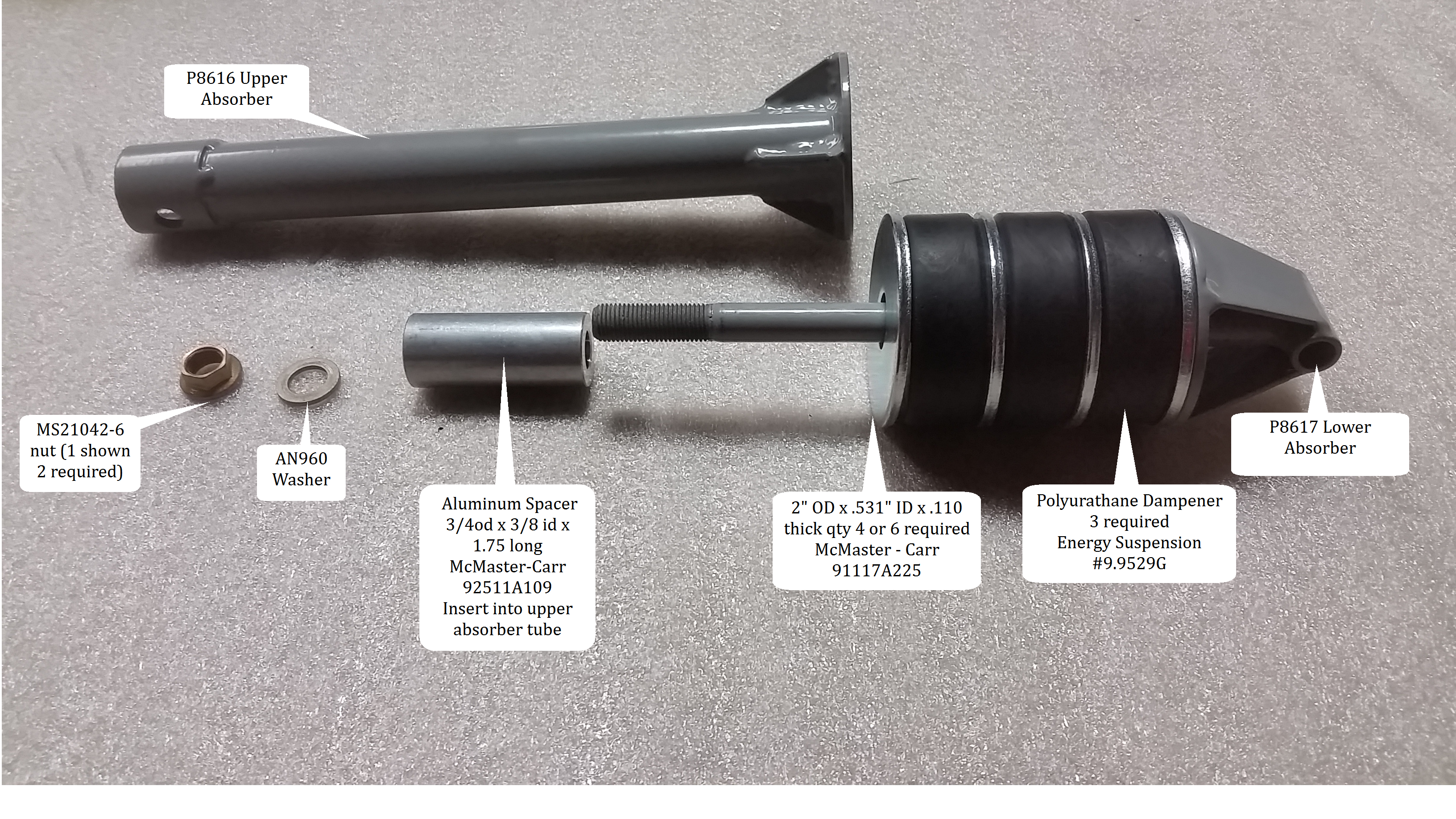

Absorber assembly

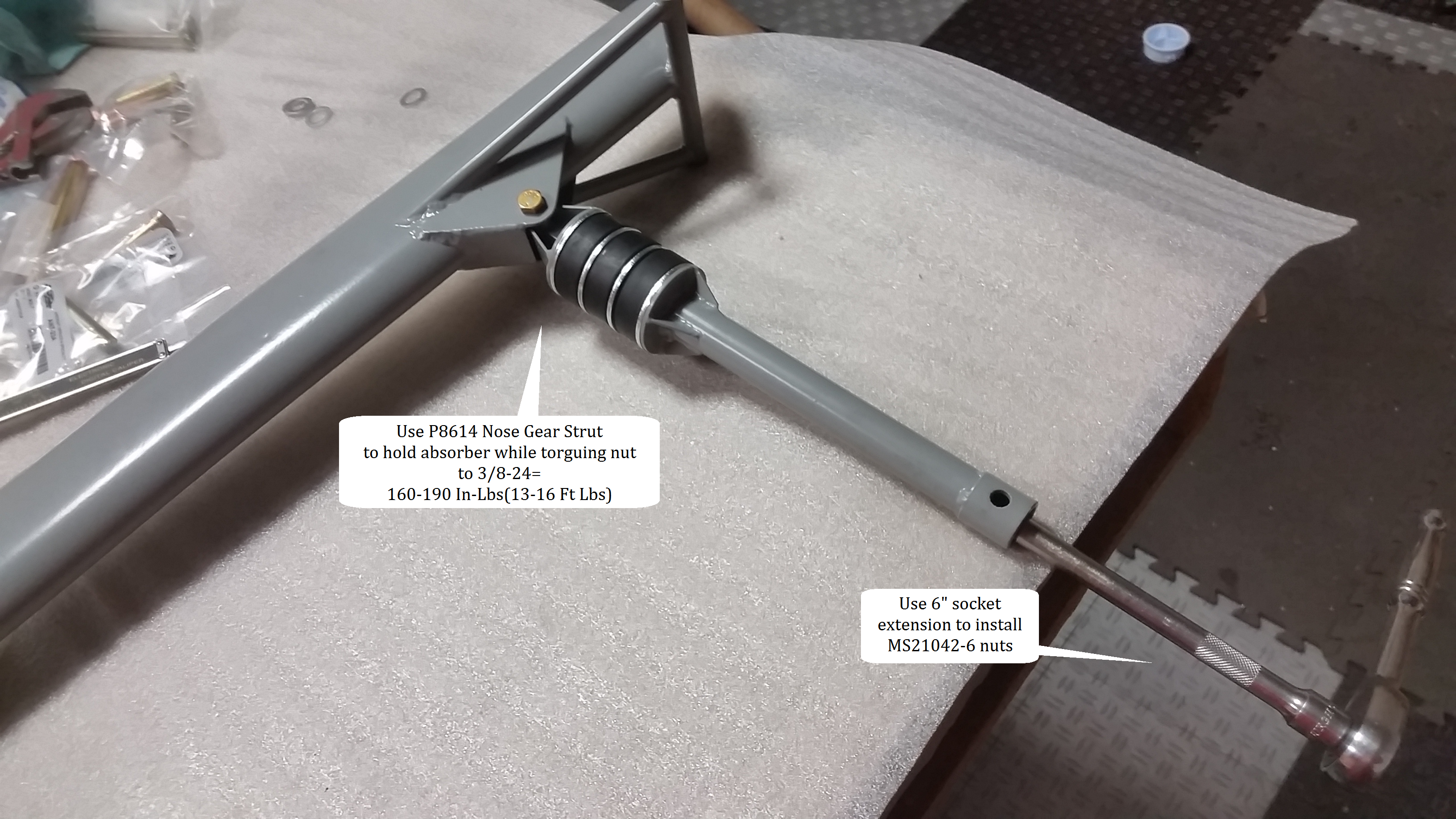

Assemble the absorber per photos below.For Aircraft using 11-400x5 main wheel tires assemble per photo. If using 5x5 main wheel tires add 1 extra steel washer on each end of the dampener "stack" (total of 6 washers). Use a small amount of " general purpose grease" one the inside and outside of the aluminum spacer. Afetr torquing first MS21042-6 nut and torque to act as a safety nut.

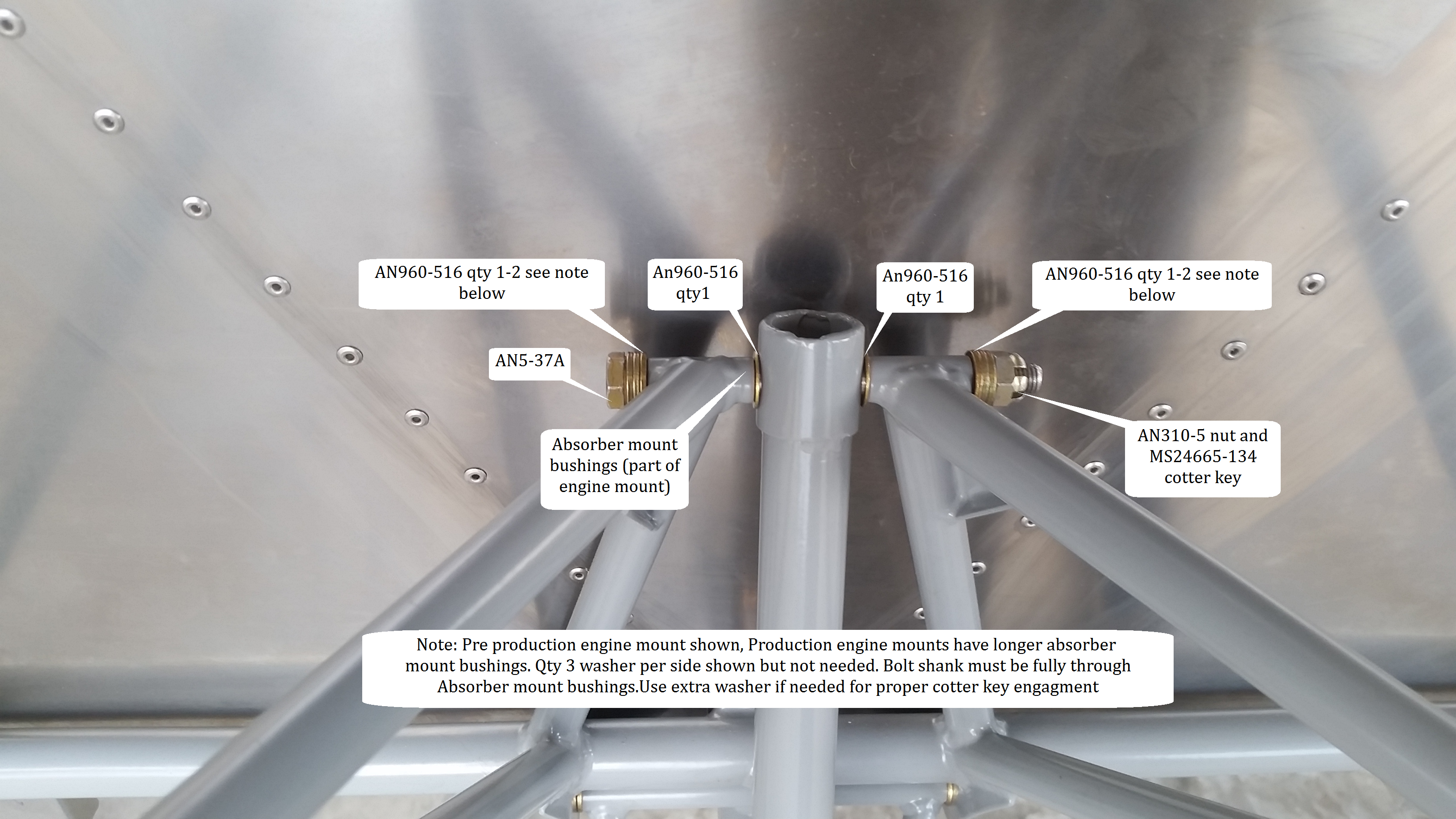

Assemble absorber to engine mount

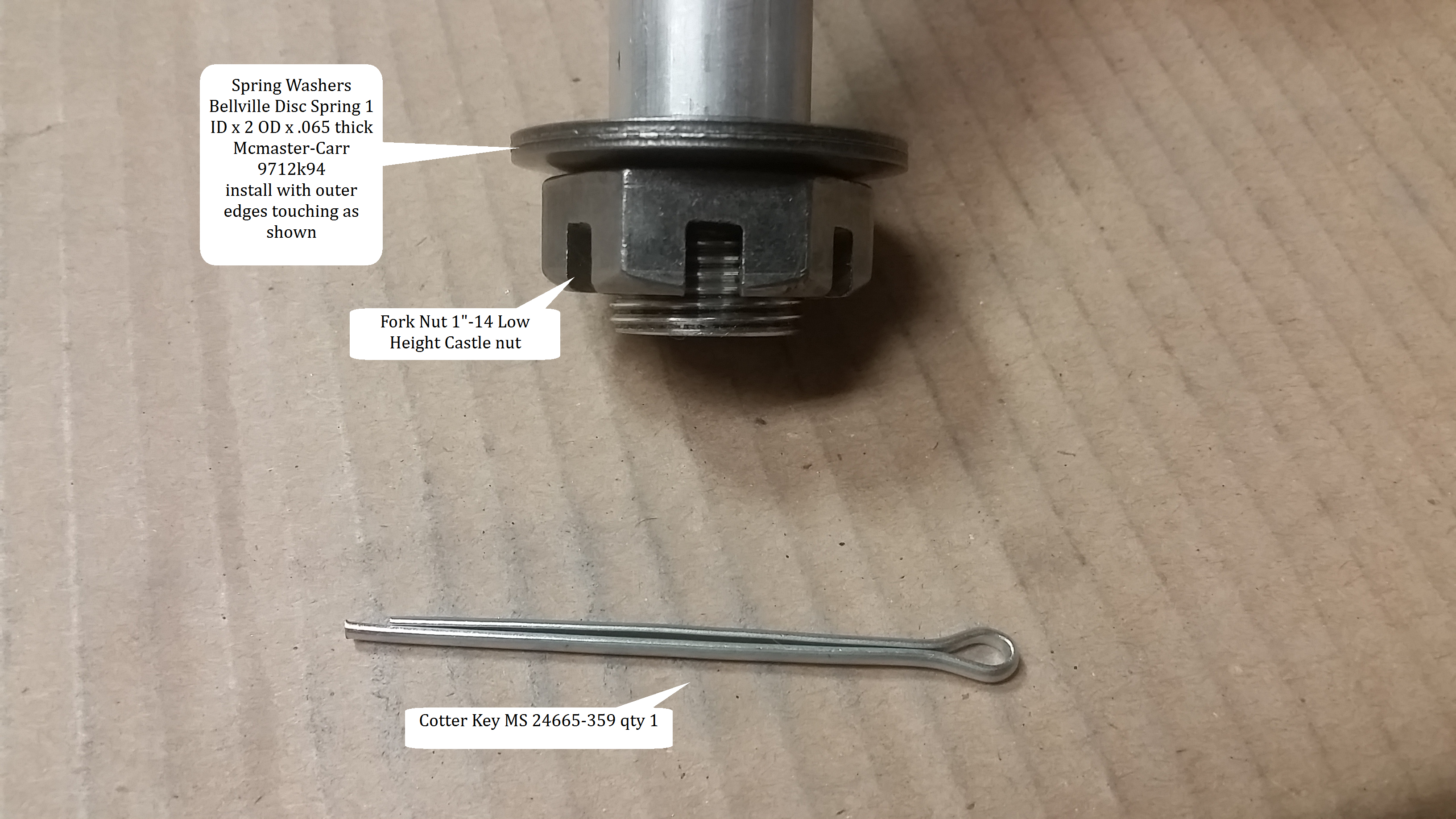

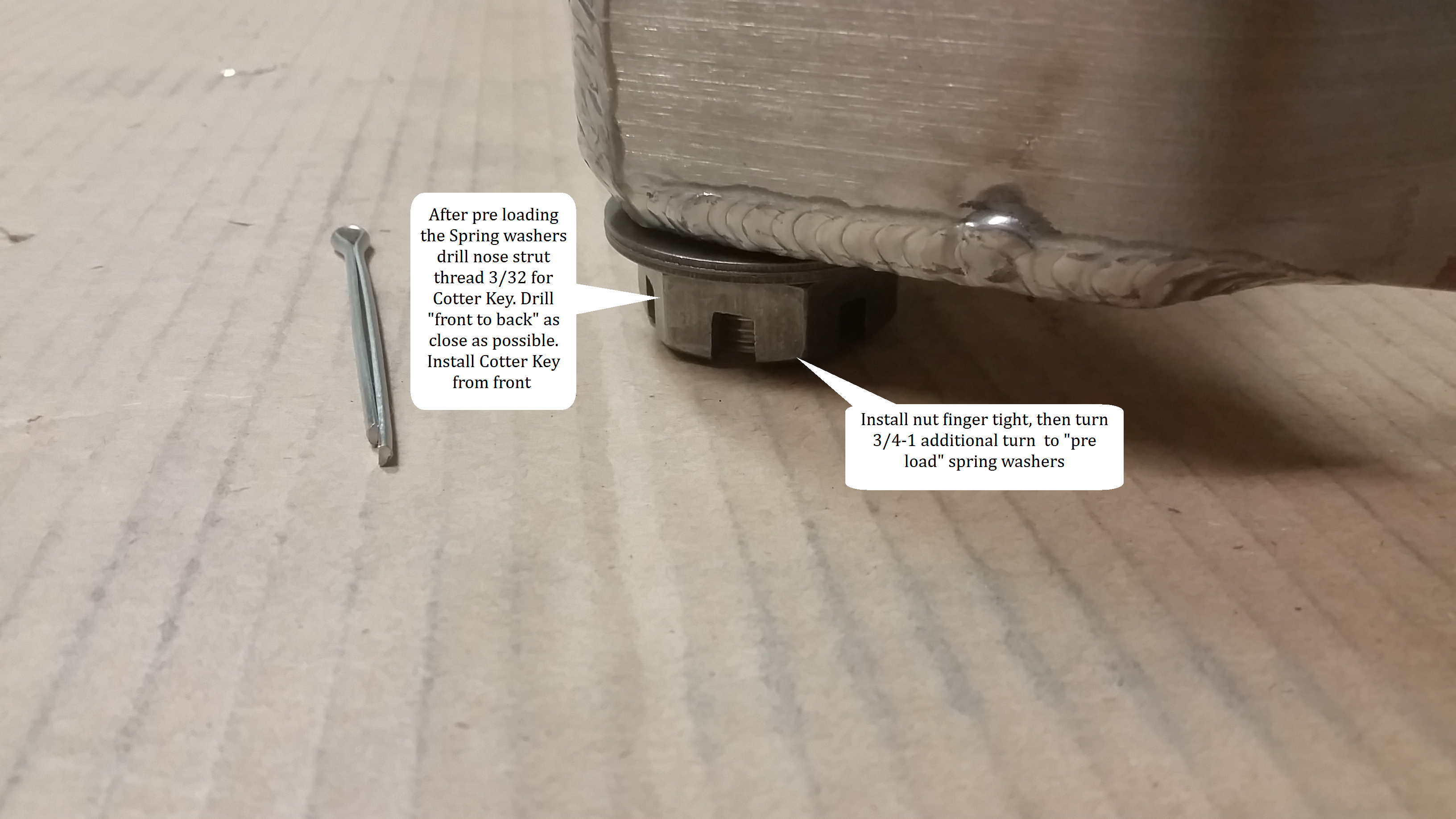

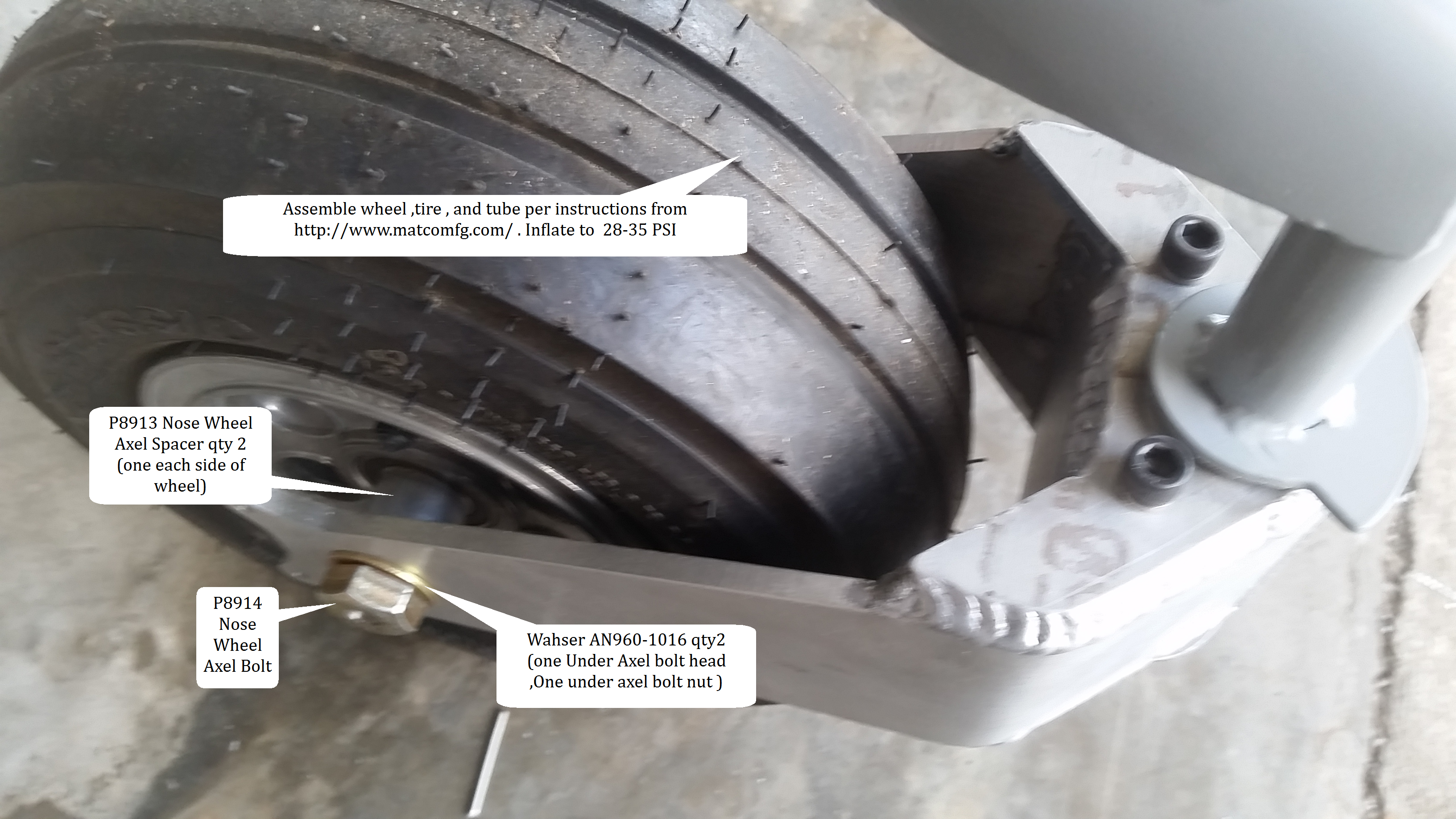

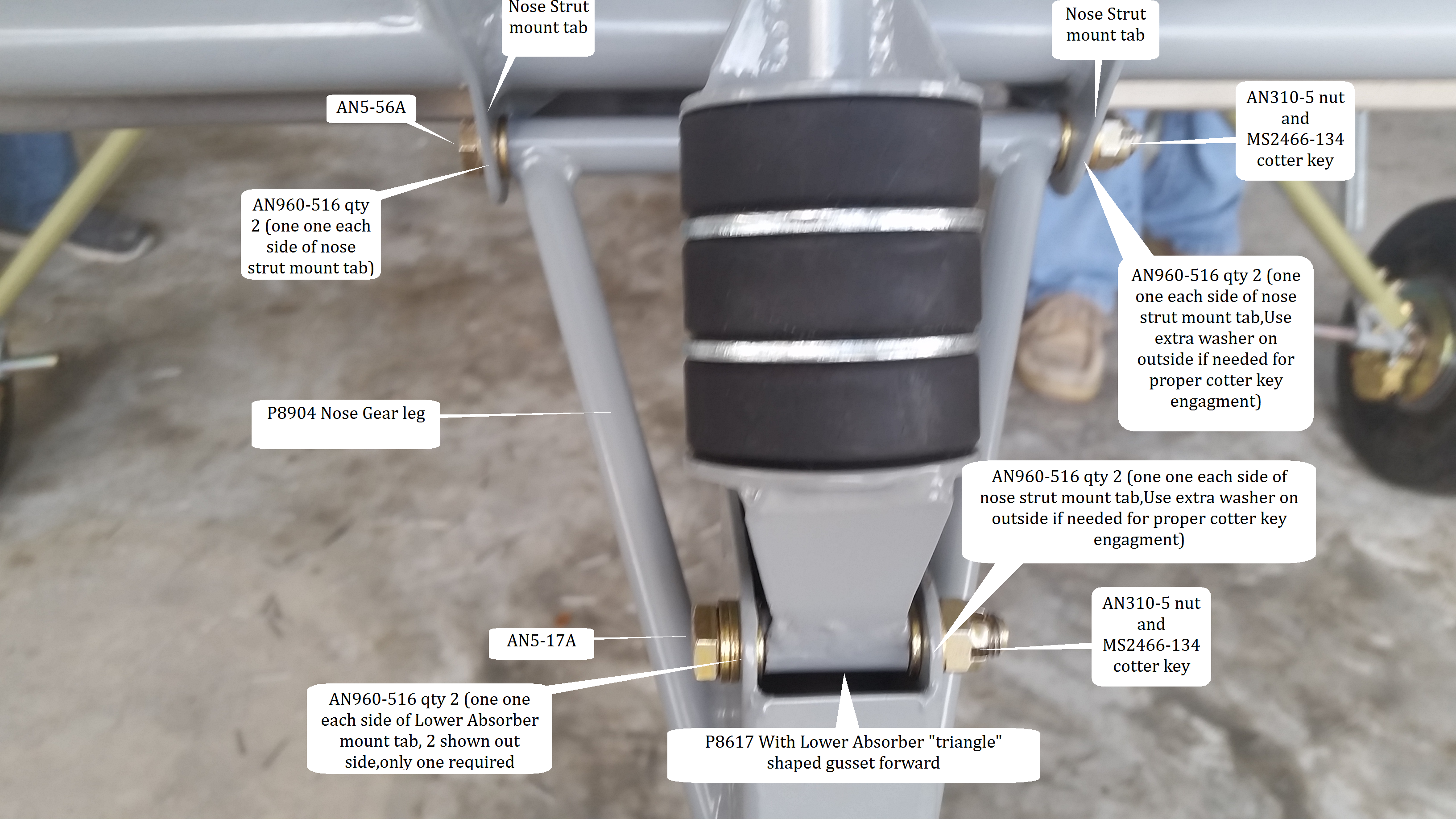

Assemble the Nose Gear Leg , Absorber , Fork,and Wheel per photos below

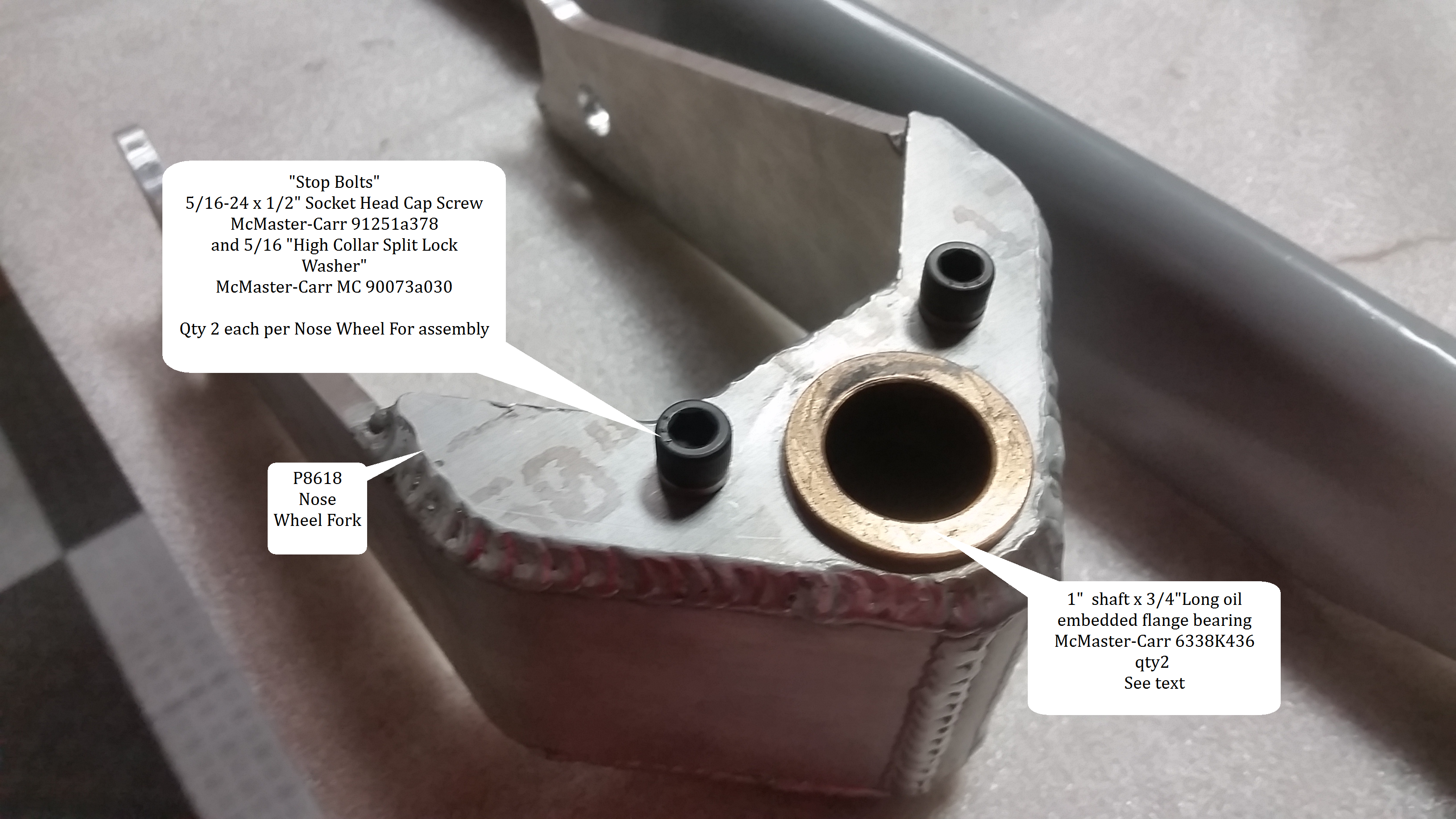

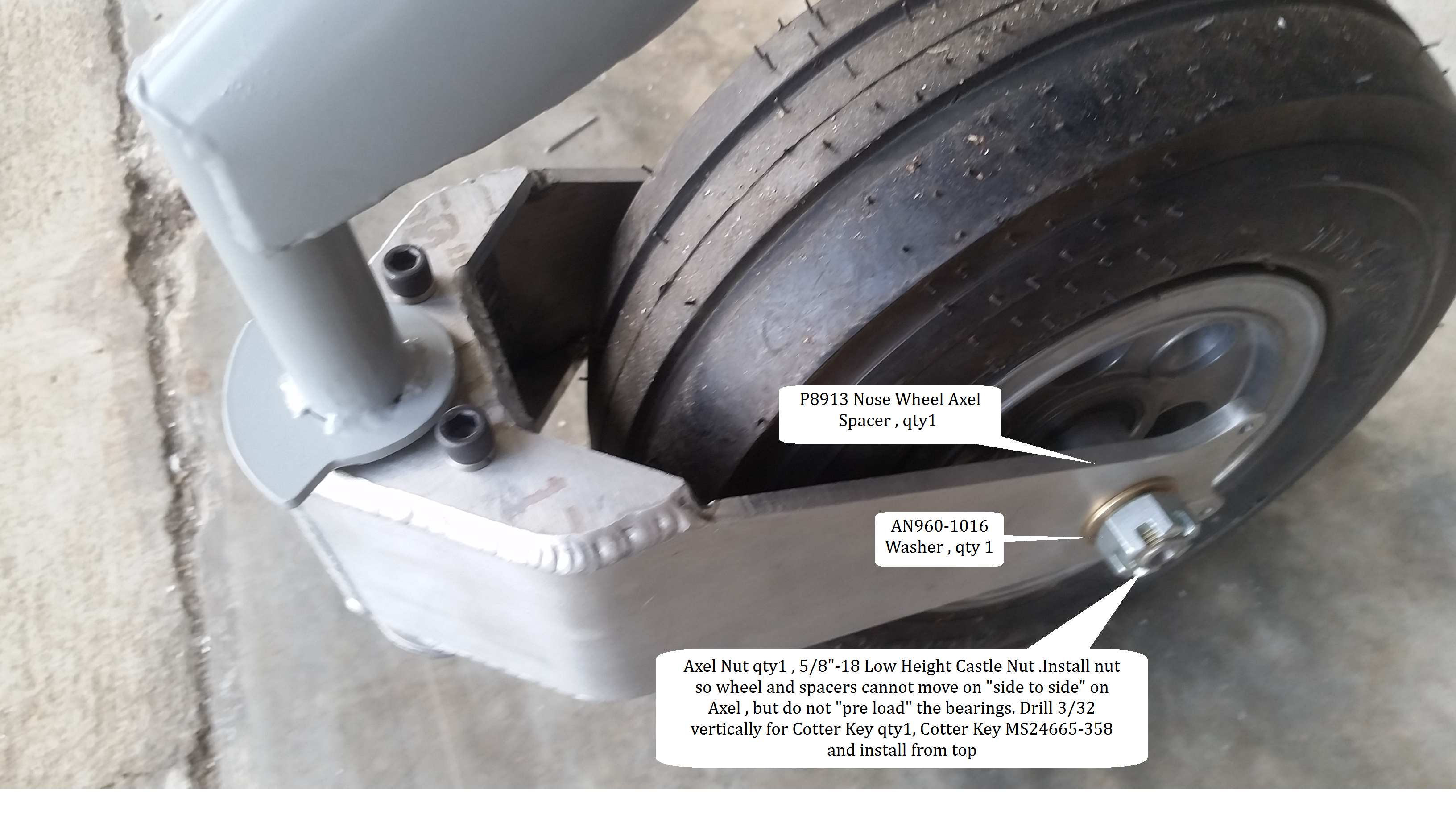

Nose Fork and Nose Wheel

The nose wheel for comes with the Flange bushings already installed and honed for the Nose Gear Legs pivot shaft. These bushings Are oil embedded , and require little lubrication. Assemble with a very light coat of general purpose grease on the pivot shaft to prevent corrosion . The bushings can be replaced if needed for wear,and honed for a snug but free to rotate fit on the pivot shaft.